Process Control in the Modern Factory

Automation and metrology are increasingly becoming vital aspects of the manufacturing process. For a state-of-the-art factory, such automation can take the form of 3D visual inspection that is revolutionizing metrology dimensional inspection standards. In today’s automated metrology, one can use three inspection types: offline, in-process, and in-line.

Offline metrology involves removing a piece entirely from the line and checking the parameters in a separate workstation. Offline metrology can be cost-effective, but slow. In addition, factories cannot use it directly for process control, and it requires far more human input.

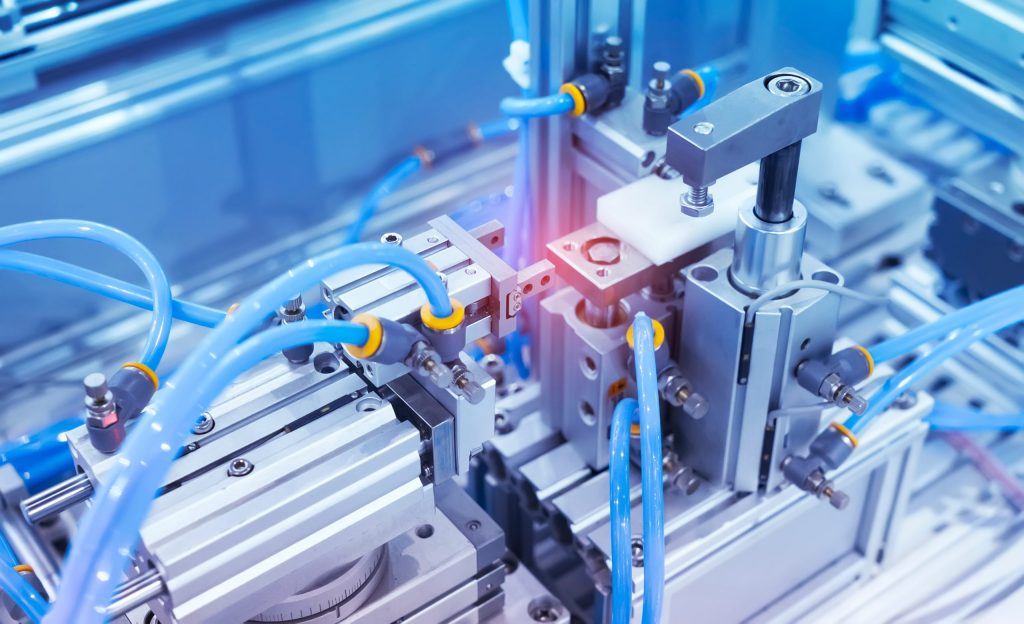

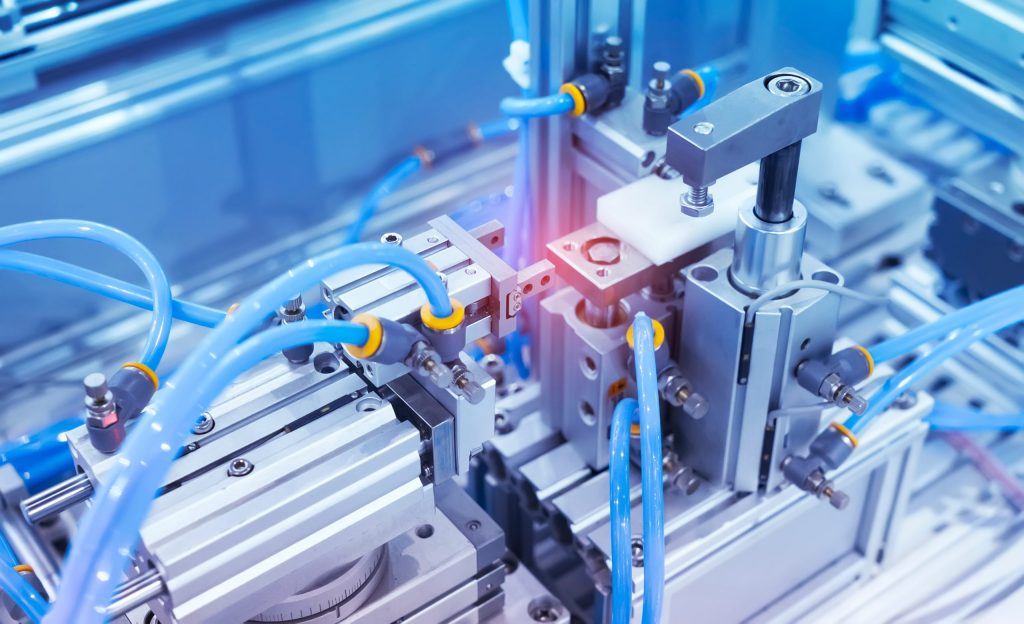

In-process metrology uses sensors within the manufacturing process, with many current systems integrating sensors into the manufacturing machines themselves. In-process metrology is especially useful for tool compensation and predictive maintenance, vastly reducing downtime.

In-line measurement is a form of automated defect inspection within the manufacturing line. In-line measurement offers a wide range of efficient, comprehensive metrology, with the added benefit of contactless solutions. Today, non-contact, in-line systems make up a considerable portion of inspection handling processes. The rising tide of automation technology has made 3D vision systems an affordable, versatile, and necessary addition to the toolbox of any manufacturer.

Why Implementing Non-Contact Inspection is the Best Move for Manufacturers

Seamless, Adaptable Integration

In-line metrology offers many powerful benefits for manufacturers. For example, its capacity for non-contact vision inspection on parts makes implementation far easier. While demanding greater computing and data-handling capacities, in-line metrology systems are far more flexible from a practical standpoint than their physical counterparts.

They can be robot-carried or pedestal-mounted, accommodating any process. Such flexibility is essential for large, complex operations or variable applications requiring quick line changeovers. Their capacity for 3D inspection also means they do not have to be error-proofed, further lowering the cost of ownership.

Rugged, Resilient Operation

Zero-contact operation avoids some of the potential pitfalls of other measurement methods. Zero-contact systems have no moving parts, relying primarily on metrology dimensional inspection software to execute the heavy lifting of the inspection process. On top of that, facilities can protect vision systems from harsh factory environments.

Advantages on the Small Scale…

Vision-based systems have a significant advantage with small, high-volume pieces. Optical systems flawlessly check every piece passing through the sensor for conformity, unlike probe sensors, which can bend, scratch, or contaminate delicate parts. The constant stream of data from automated in-line inspection also opens new doors for precise process control and up-to-the-second performance analysis.

…And the Large Scale

Non-contact metrology dimensional inspection isn’t just limited to 2D systems either. 3D dimensional inspection systems provide detailed process data for intricate parts, delivering low-maintenance and 100% reliable process control. This is a game-changer for larger parts that would take significant time to measure offline.

The same is true for surface inspection. Automating high-resolution profilometry allows for dimensional quality inspection, while maintaining efficiency. You don’t just have to imagine the possibilities, either. See how RōBEX uses visual inspection systems in real factory settings.

In-line Visual Systems Meet +Vantage Engineering

RTV Inspection for Sealant Applications

Ensuring the integrity of structural adhesives and sealants is a vital part of the vehicle manufacturing process. As a heavily automated industry, both the application and inspection of the adhesive bead naturally become automated processes. However, while errors in the bead can be evident to the human eye, dimensional quality inspection requires highly advanced systems to work effectively.

In one instance, for example, a faulty delivery mechanism led to the head plowing through the bead as it dispensed it. Such a bead resulted in insufficient wet-out, leading to serious safety concerns.

Luckily, +Vantage’s powerful inspection system performed a complete non-contact metrology dimensional inspection, providing detailed, unobtrusive data on the delicate process. Where traditional tolerancing parameters—even though using bead height and bead width— would’ve passed the parts, our system was able to save customers potentially tens of millions of dollars on leak damage.

Automate with Us!

Want to learn more about in-line visual inspection automation? Download our brochures!

To discover the detailed +Vantage integration process and the vast array of automation services we offer, visit our website.

To discuss how our systems can benefit your custom process, contact us to speak with an engineering design consultant today!