Automation Integration Makes the Difference for Electric Vehicle Companies

At RōBEX Corporation, we stay on the cutting edge of manufacturing technology, and support those at the forefront of their industry through our expertise. As the world goes green and consumers become increasingly aware of the dangers fossil fuels pose, consumer demand for electric vehicles (EVs) has skyrocketed, as has their market share.

At RōBEX Corporation, we stay on the cutting edge of manufacturing technology, and support those at the forefront of their industry through our expertise. As the world goes green and consumers become increasingly aware of the dangers fossil fuels pose, consumer demand for electric vehicles (EVs) has skyrocketed, as has their market share.

To keep up with this demand for products, original equipment manufacturers (OEMs) have been exploring increasingly automated solutions for the EV manufacturing process. The secret to automation success lies in a strong knowledge base, and RōBEX has the expertise to support an efficient future for electrical vehicle production.

A Growing Market for EVs

Tesla emerged in the EV market in 2003, but it wasn’t until they introduced their mass-production Model 3 in 2017 that the market for electric vehicles exploded. Since then, the industry has seen a 67% jump in EV sales from 2019 to 2020, with even greater growth projected in the coming years.

Legacy automakers like Chevy, Ford, Toyota, and others are joining the EV game, along with newcomers like Rivian and Lucid Motors. In a crowded field, success or failure hinges on these companies meeting the unique challenges of the electric vehicle manufacturing process. But why is building a commercially viable electric vehicle so difficult?

Manufacturing Challenges for EV Assembly

Manufacturing Challenges for EV Assembly

As any production engineer can attest to, creating a new production line is never simple, especially when the goal is to maximize automation. Tesla learned this firsthand when they attempted to construct Elon Musk’s “Alien Dreadnought”, a Model 3 production line almost entirely devoid of human operators and handmade components.

While Tesla has undoubtedly been a commercial success, their quality assurance has suffered as a result of subpar integration and automation. J.D. Power ranked Tesla dead last on their quality rankings, while customers have reported everything from sunroofs flying off at highway speeds to leaking headliners.

Lights-out manufacturing may still be an overly ambitious dream today, but improving automation systems are bringing us continuously closer. With proper system integration through your assembly, automation, and inspection systems, quality control issues don’t need to be a feature of EV assembly. RōBEX has the tools, capabilities, and partners to guide you along the way.

How Are Electric Cars Manufactured?

To understand the challenges of the electric vehicle manufacturing process, and how automation integrators like RōBEX can help, it’s important to know the steps that go into car production. Here are the basics of the assembly process, and where our unique automation solutions benefit electric vehicle companies.

EV Assembly and Automation

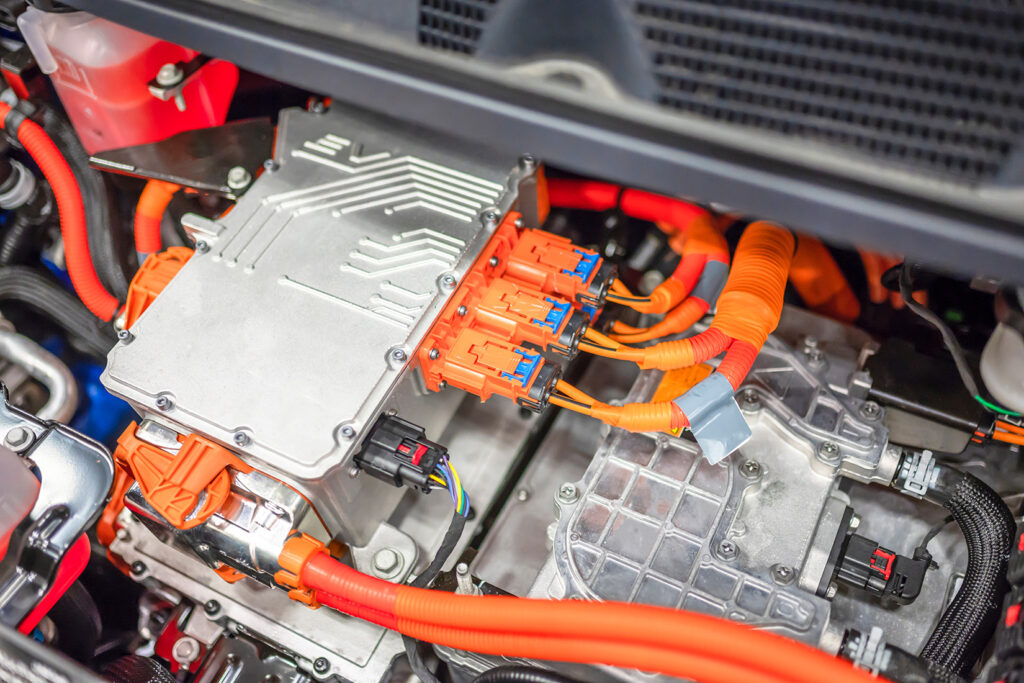

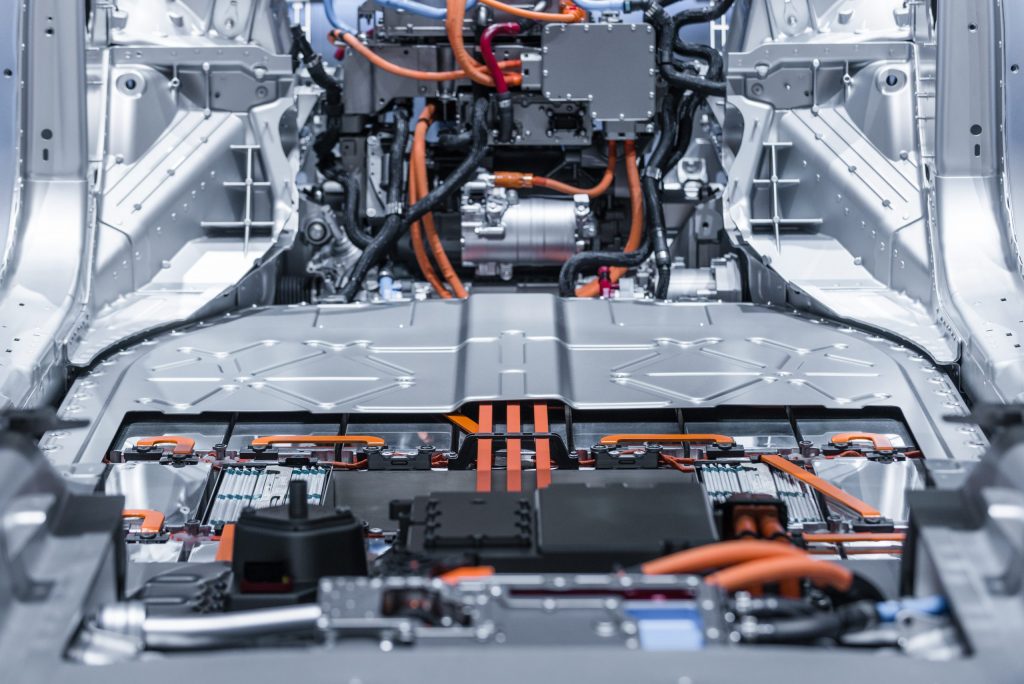

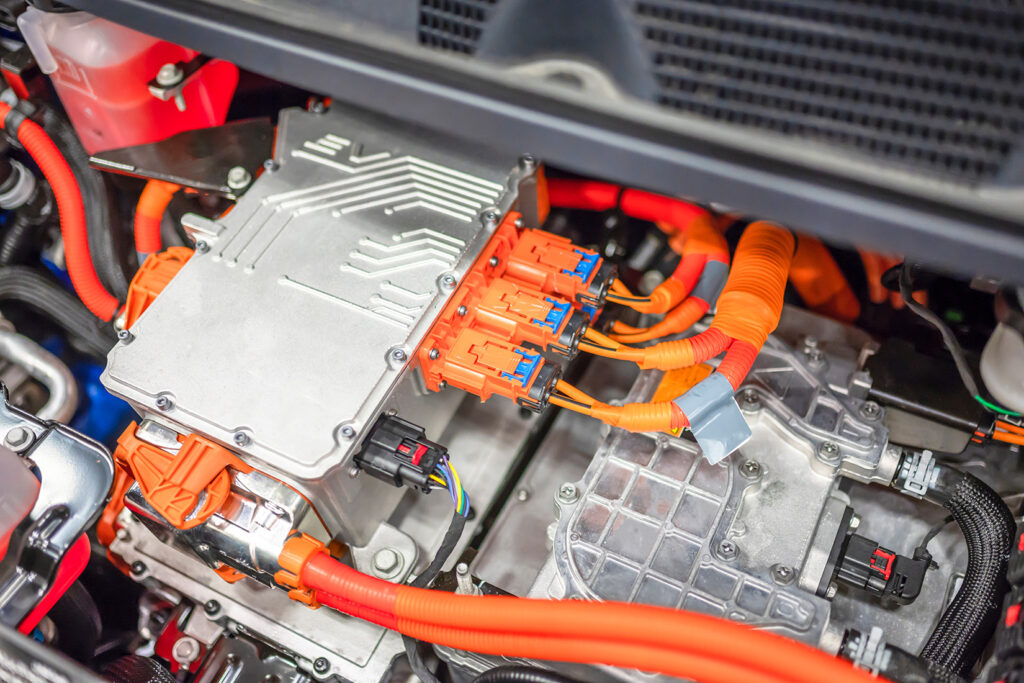

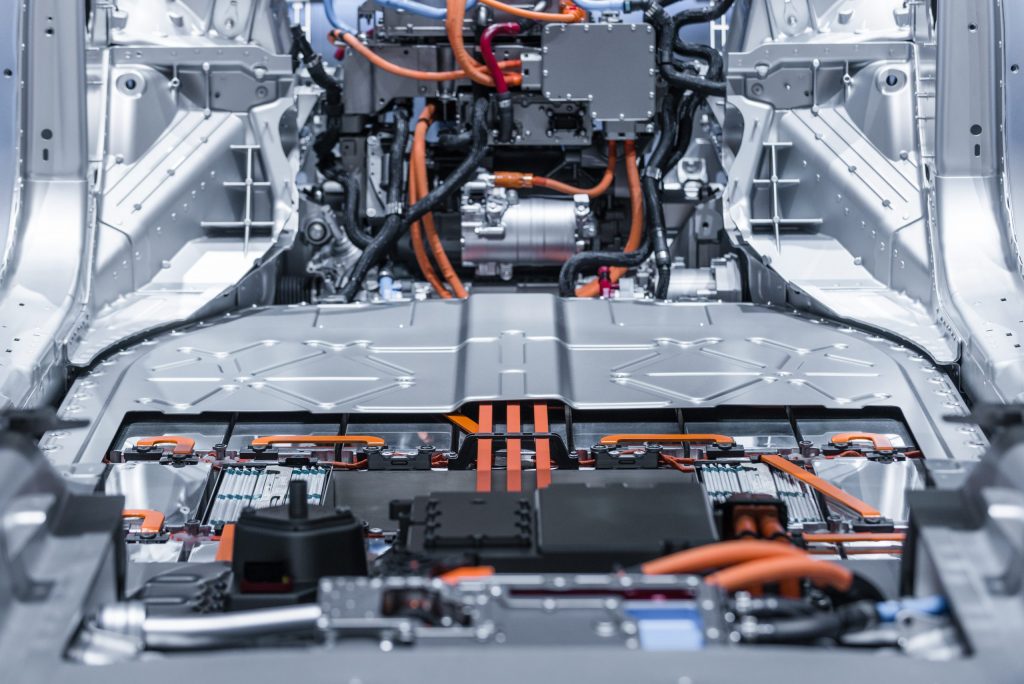

In many ways, electric car assembly largely follows the same lines of production as their internal combustion engine (ICE) counterparts. However, the big differences emerge at the drivetrain and the battery packs. Battery packs in particular require a complex fabrication and assembly process.

RōBEX Corporation is an industry leader in integrated automation solutions. From our 50,000 square foot factory, we act as a single source system integrator for precision systems.

Robotic assembly is rapidly becoming a mainstay in the automotive industry, and we have the expertise to develop seamlessly integrated systems running off PLCs. Each of these is in constant communication with the rest of the manufacturing line, reducing operator involvement and allowing for in-situ statistical process control (SPC).

Our assembly and automation expertise allows electric car makers to build advanced production lines. This includes fully automated systems with machine part tending, semi-automatic systems for predetermined operator involvement, and specialized processes for pressing, torquing, riveting, and joining systems.

The EV Inspection Process

Arguably, inspection automation is just as important as assembly in developing a precise, efficient production line, and RōBEX excels here too. Our in-line metrology equipment runs the gamut from 2D and 3D vision systems to 100% automated inspections cells, which output to the SPC system of your choice.

Inspection is doubly important for the EV manufacturing process, as the battery packs feature numerous engineering challenges not found in ICE vehicles. During the manufacture and assembly of battery packs, you need to ensure stack alignment, injection seal integrity, and weld inspection of the cells, among numerous other parameters.

Vision Systems Provide Powerful Solutions

Vision Systems Provide Powerful Solutions

This is why RōBEX partners with a variety of vision system providers including Cognex, Keyence, LMI, and others for our vision and inspection systems. Through partnering with fellow industry leaders in the field, RōBEX is an expert in gauging and inspection systems for EV battery assembly.

These same inspection systems allow for rapid go/no go measurements by camera systems, which can quickly compare components against a master CAD model, ensuring you won’t find any gaps in the bodywork or other critical components. This also allows for the implementation of other poka-yoke processes, further ensuring quality control and avoiding dangerous oversights.

Automated Leak Testing Ensures Safety

Among the many end-of-line inspection solutions we offer, leak testing is perhaps the most important for an electric vehicle, ensuring the batteries remain safely sealed under adverse conditions. Proper sealing prevents the formation of rust and corrosion in vital parts, which may lead to an electrical fire. We offer fully integrated leak testing systems in the method of your choice, from sniffing and spraying to bombing and accumulation testing.

The RōBEX Electric Vehicle Automation Advantage

While establishing a streamlined EV assembly line has its challenges, RōBEX is ready to make sure you can deliver a quality, defect-free product for ecologically minded car companies. Want to learn more about RōBEX electric vehicles? Contact us today to find out how we can accelerate your EV production for a competitive advantage.

At RōBEX Corporation, we stay on the cutting edge of manufacturing technology, and support those at the forefront of their industry through our expertise. As the world goes green and consumers become increasingly aware of the dangers fossil fuels pose, consumer demand for electric vehicles (EVs) has skyrocketed, as has their market share.

At RōBEX Corporation, we stay on the cutting edge of manufacturing technology, and support those at the forefront of their industry through our expertise. As the world goes green and consumers become increasingly aware of the dangers fossil fuels pose, consumer demand for electric vehicles (EVs) has skyrocketed, as has their market share. Manufacturing Challenges for EV Assembly

Manufacturing Challenges for EV Assembly

Vision Systems Provide Powerful Solutions

Vision Systems Provide Powerful Solutions