At +Vantage, metrology technology is one of the cornerstones of our business. Our systems allow you to integrate your inspection and measurement technology seamlessly within your business. To this end, we want to discuss the incredible value of advanced metrology solutions and inline gaging for your automated process, and how it can improve throughflow, traceability and reduce process downtime.

What is Inline Metrology?

Inline metrology is commonly understood as the process of automatic measurements executed and integrated within the manufacturing process. This is to say the parts are not removed from the automated cycle in order to be inspected.

In a traditional offline inspection process, a part goes through a long, manual process as follows.

- The part is removed from the manufacturing flow by hand

- The part is placed within a measurement gauge or CMM

- Measurements are recorded

- A pass/fail is determined for the part

- The part is either placed back into the manufacturing flow or discarded

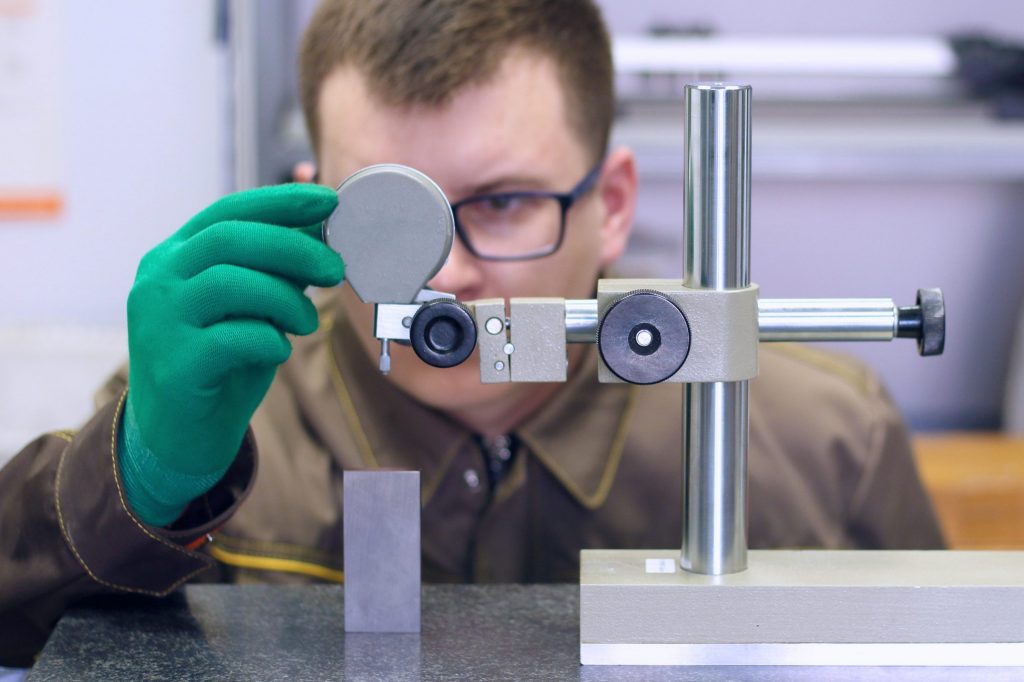

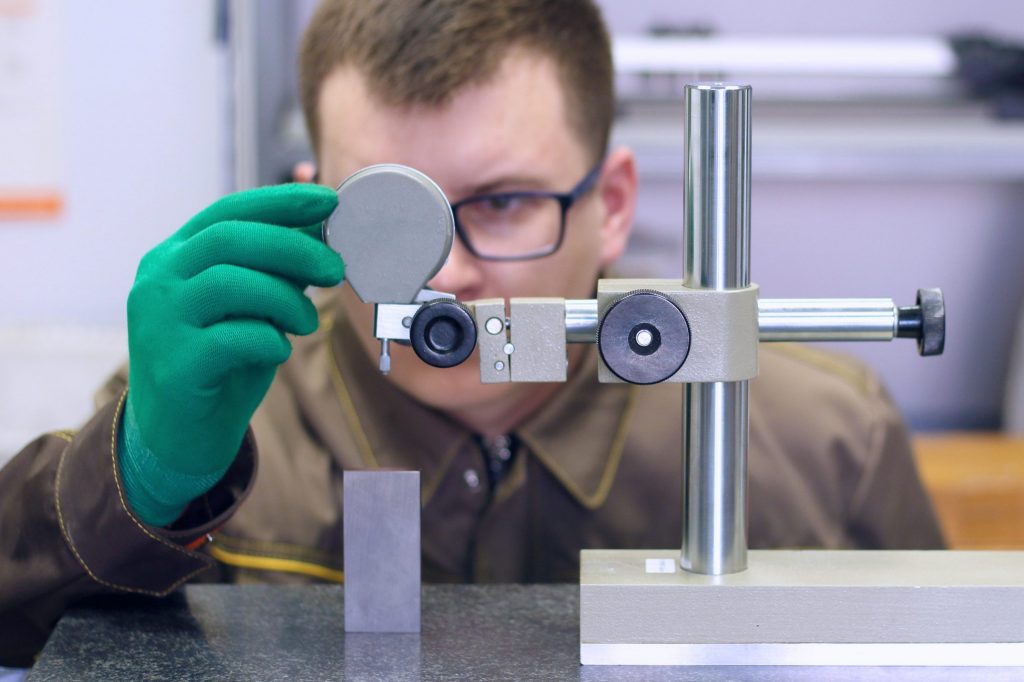

Automatic metrology can take several forms, using contact probes or visual inspection depending on the needs of the process. By not interrupting the flow of production, these systems vastly increase the consistency and speed of the measurement, eliminate human error, and allow for process control through constant data collection.

What Does Offline Inspection Cost?

Offline inspection is not just inefficient, but costly to your production line. This is true in terms of lost productivity, man-hours, and potential defect inclusion in your final production batches. Offline inspection processes require keeping a fully staffed metrology lab on-site and staffed, running shifts on the same schedule as your production cycle in order to evaluate components from each production run, and then returning parts in time to be processed with the rest of their batch.

Each individual chain in this process requires a human operator to remove a part from the line, handing it off to a technician for inspection, and then either returning it or designating it as defective. Each link in this chain also opens the door to human error. An operator may not label the test article correctly. Or a metrology technician on the third shift may misread results amidst the chaos of a busy lab at late hours, letting rejected parts find their way back into the production cycle.

Ultimately, this harms the traceability of your product if not breaking the traceability chain entirely. This costs you time to recall defective parts, as well as the man-hour costs associated with the above human labor. Fortunately, implementing inline metrology automation slaves these problems while offering a plethora of benefits.

What Does Inline Gaging Add?

Manual CMMs are always a necessity for any production line, giving you the baseline for precision and allowing you to designate master specimens to compare against. However, inline inspection is the superior option for moment-to-moment inspection during the production process. Inline inspection does not require human intervention, nor the removal of parts from the production line. Instead, it acts as a step, seamlessly integrated into the production process itself.

Inline inspection, through inspection gauges, vision cameras, or the metrology method of your choice, may be entirely automated. This may be achieved by allowing an armature or other robotic fixture to take a sample from the prior step, place it within the test cell, issuing a pass/fail, and then placing the test article accordingly.

Inline metrology also offers the added benefit of automatically reading whatever bar codes, laser making or other information has been encoded onto the part. This ensures quality information is directly transmitted to your Manufacturing Execution System (MES) software without the need for manual data entry. It also enables powerful process control to easily track the quality of rapidly-moving parts.

How Does +Vantage Make Inline Inspection Work For you?

Our decades of experience in metrology and automation, combined with our role as your single source supplier and system integrator, places +Vantage into a unique position for providing you with automated, inline inspection technology.

We offer a broad range of automation solutions, and since all of our machines are fully integrated, this allows for tool compensation between CNC and test cells for fully automated handoff. It also allows for the automatic capturing of quality data for Statistical Process Control (SPC), a task that would otherwise be offloaded to a lab technician for manual entry after each run of a CMM.

Automated inline metrology is the future of manufacturing quality assurance, and +Vantage has the skills to make it work for you. If you want to learn more or get started on a project, please contact us!