Dimensional Measurement

RōBEX provides comprehensive automation solutions for precision industries, utilizing advanced measurement technology to deliver powerful, durable systems.

RōBEX provides comprehensive automation solutions for precision industries, utilizing advanced measurement technology to deliver powerful, durable systems.

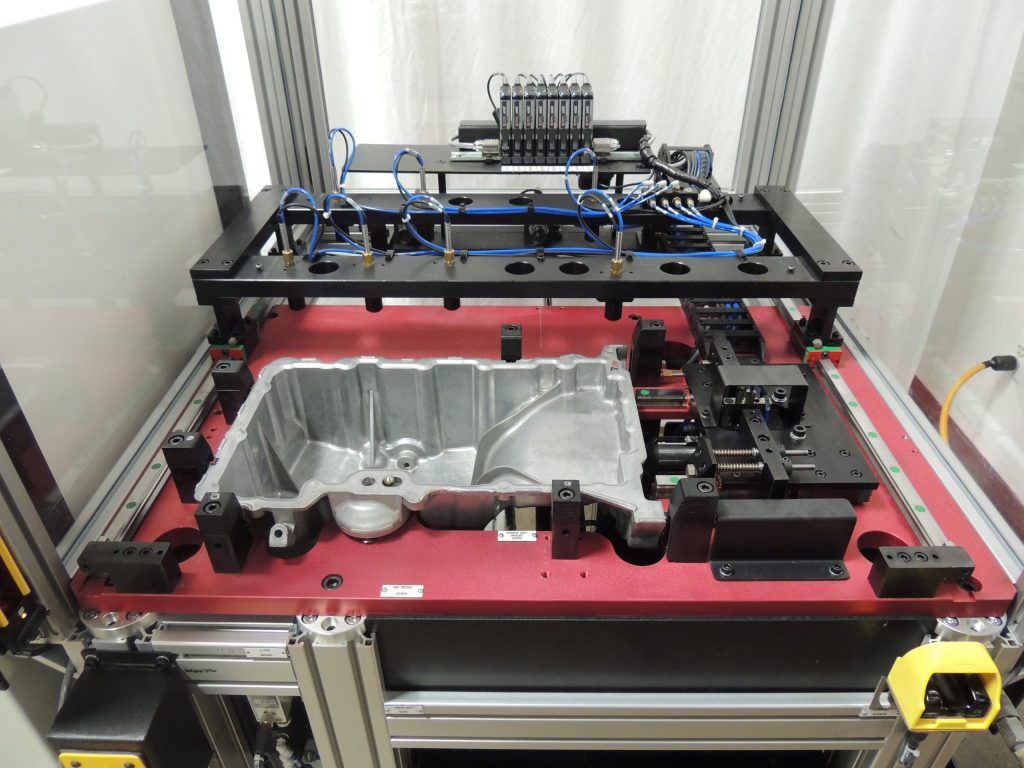

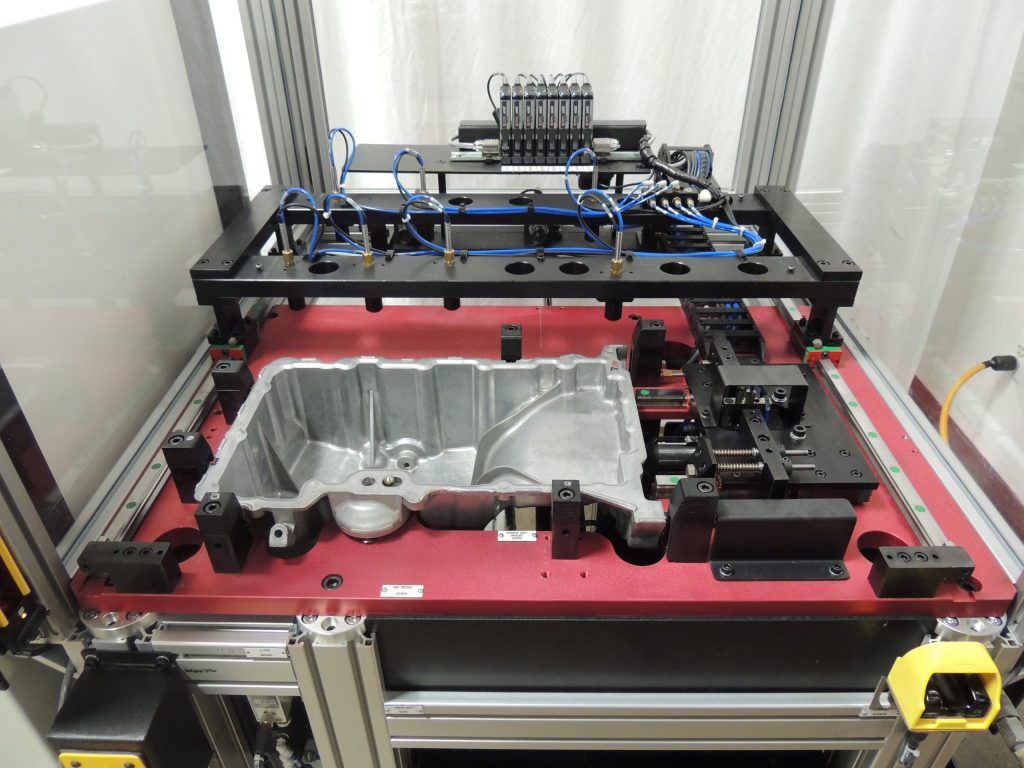

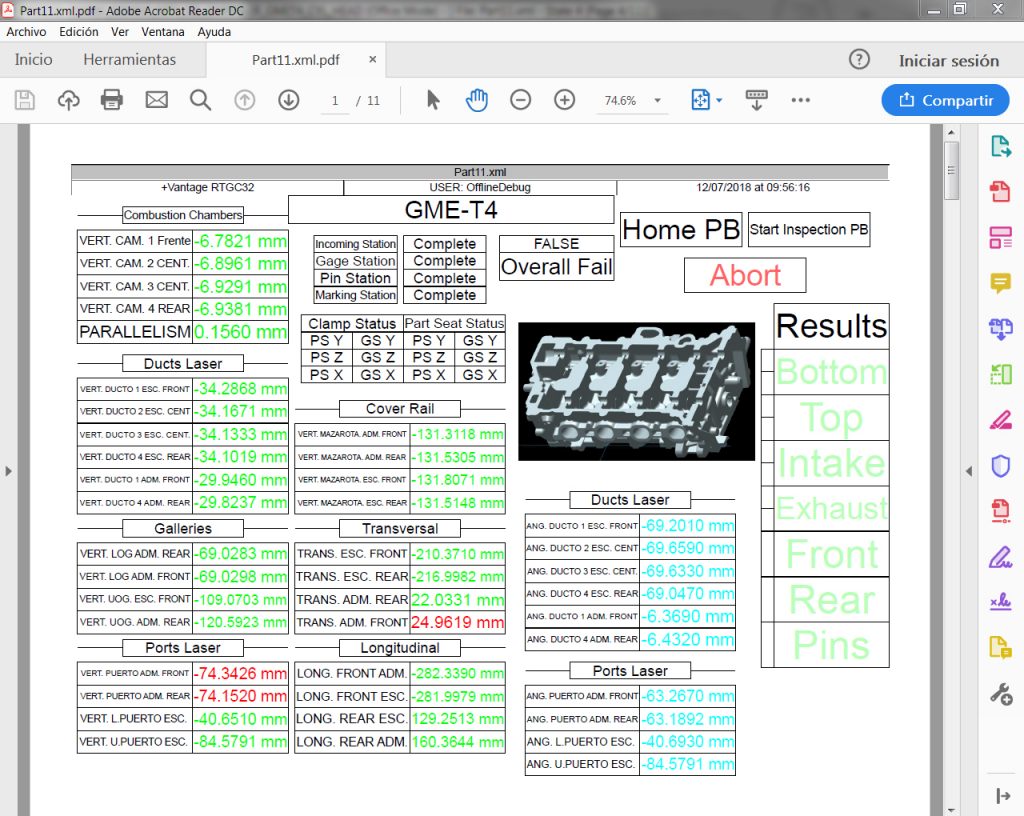

End-of-line inspection and testing are crucial to your quality assurance (QA) process. For precision manufacturers, RōBEX offers comprehensive geometric and dimensional tolerancing (GD&T) inspection solutions. Our systems reduce the need for waiting on CMMs, increasing your precision and throughput. RōBEX delivers sub-micron resolution for your measurement solutions, providing an unmatched in-line dimensional measurement for CMMs on the production floor.

RōBEX develops custom gages for high precision inspection to the sub-micron repeatability and finds solutions to offer our customers 10% GR&R and better for their critical process tolerances. We have built and delivered gages worldwide, and we will find the correct technology to best suit the process and conditions at hand. Whether it be air gages, contact gages, non-contact gages, or 3D systems, we have the experience and expertise to deliver the best systems for your automation needs.

RōBEX gage systems feature Linear Variable Differential Transducer (LVDT) contact sensors for dimensional measurement of machined, ground, and casted parts. Dimensional gage systems can be valuable for inner diameter (ID), outer diameter (OD), length, taper, and the full slew of GD&T relevant values to ensure you stay within tolerance. The LVDTs are integrated with protective shells to stand up to harsh factory environments. This prevents accidental damage and unnecessary wear, providing unrivaled durability for your quality control for any application.

These LVDTs offer incredible precision and speed, performing GD&T measurements on critical machined, ground, casted, and forged features. By checking specific spots on a piece against points on a CAD model, you can verify the flatness, profile, perpendicularity, and feature positions on vital parts within seconds. These dimensional gage systems also allow for comprehensive process control, tracking process fidelity across a cycle.

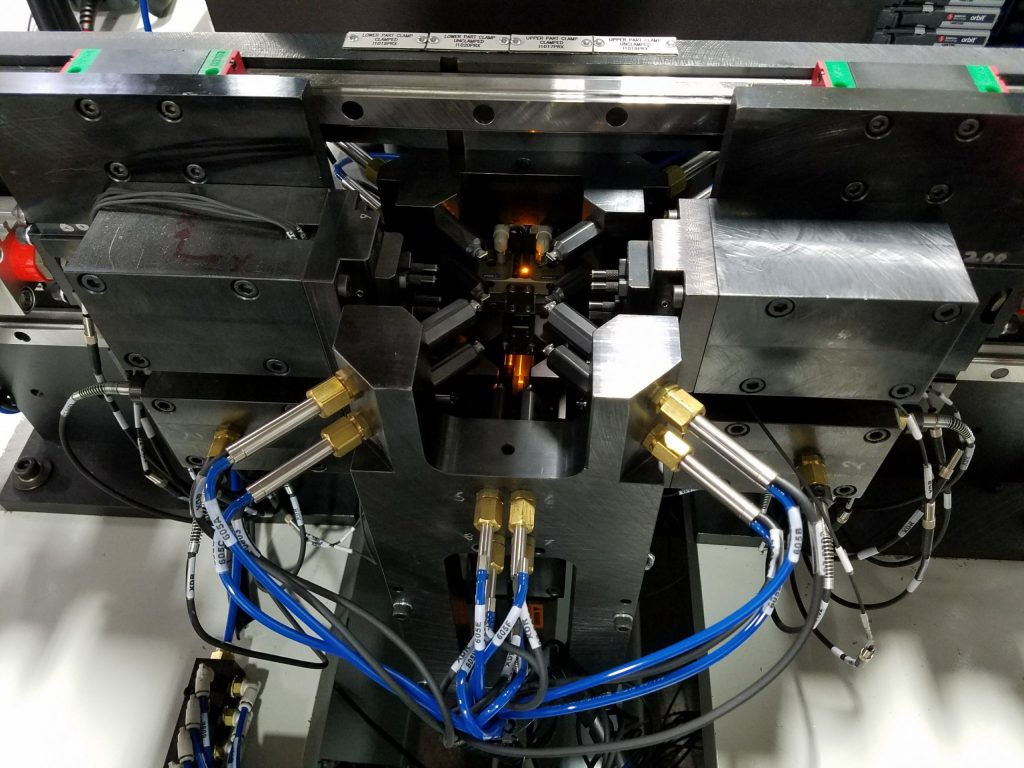

Pneumatic comparator gauges, commonly known as air gauges, function by measuring changes in airflow from a nozzle close to the surface of a piece. This acts as a highly precise, contact-free means of measuring internal and external diameters, as well as many other features. The unique qualities of air gauge sensors make them highly flexible, well suited to abrasive factory conditions, and able to access difficult spaces LVDTs may not reach. Our custom in-line dimensional measurement technology provides easy integration, delivering powerful automated inspection solutions for your process.

NEED FURTHER INFORMATION OR

CONTACT US

automation@robex.us

+1.734.432.5055

8600 S Wilkinson Way, Perrysburg, OH 43551

Get in Touch

RōBEX

1745 Indian Wood Cr

Suite 210

Maumee, OH 43537

© 2024 RōBEX – Industrial Automation, Metrology and Manufacturing Systems Integration. All Rights Reserved